Jinan Dayi Expansion Machinery Co., Ltd. is a professional manufacturer of bread crumb production equipment. Our fully automatic bread crumb production line has carefully designed manufacturing processes. The bread bran production line equipment is designed based on twin-screw extrusion technology, and its quality and operation meet the standards. The bread bran production line developed by our company has changed the traditional production process of bread bran.

The production process of bread bran production line equipment is fully automated, including mixing, extrusion, cutting, crushing, and drying. In addition to flour, available raw materials include Rice noodles, corn flour, corn starch, soybean flour, etc. Bread bran is widely used as a food additive and as a surface coating for fried foods such as fried chicken, fish, seafood (shrimp), onion rings, etc. Its taste is crispy and delicious, with rich nutrients. Change the process; We can produce various shapes of bread crumbs, including needle shaped, granular, snowflake shaped, flake shaped, star shaped, or various shapes, to meet the different needs of customers.

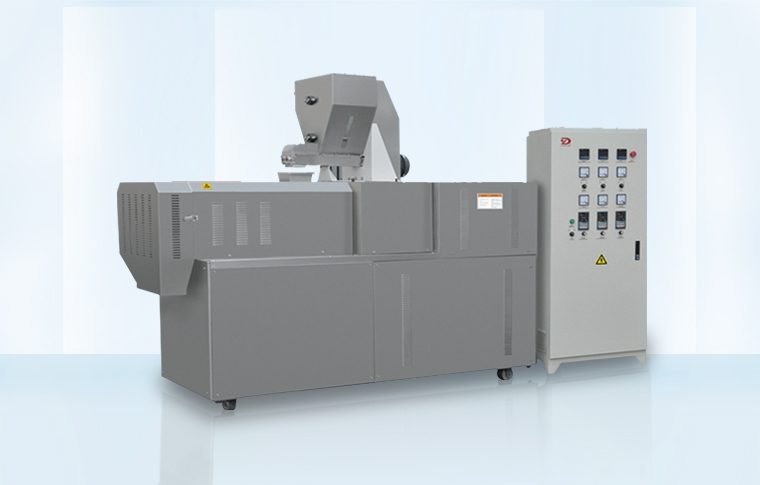

The design of the bread bran production line equipment is reasonable, with strong stability, and the level of automation has reached a certain level. This fully automatic bread crumb production line is easy to operate and learn, with precise parameter control to ensure that the product is completed within specific temperature, pressure, humidity, and time. Bread bran is a widely used food additive, mainly used for deep frying Western dishes such as steak and chicken legs. Our company has developed a bread bran machinery based on market needs, which is a fully automatic production line that includes raw material mixing, conveying, steaming and maturation, forming, drying, and finished products.

Bread bran production line compared with traditional production processes, it has fewer production personnel, shorter production processes, higher unit yields, energy efficiency, and reduced production costs; Simple equipment matching, small footprint, and convenient operation; No waste, no sewage or exhaust gas generation, green and environmentally friendly without pollution; Widely used raw materials, easy to change product variety and shape, and more diverse products.