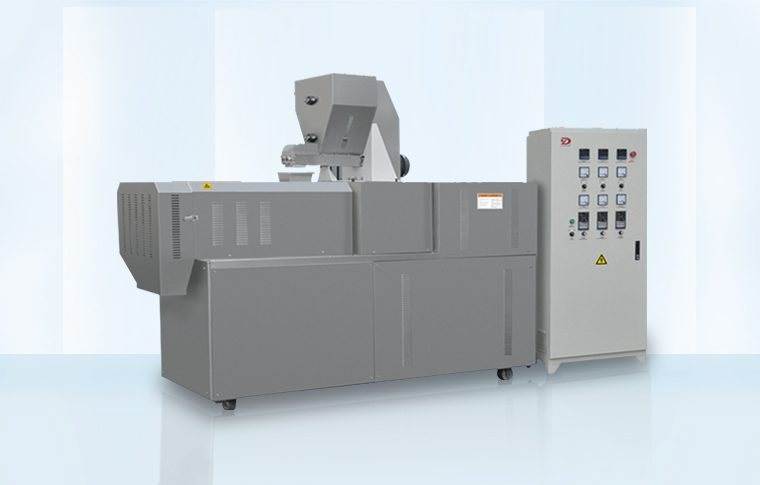

This core filling snack production line has the characteristics of multiple optional models, flexible equipment configuration, wide range of raw materials, multiple product types, and simple operation. By changing different molds and changing production processes, various popular puffed foods in the market can be produced, suitable for various food manufacturers.

The core filling snack production line equipment production line is highly automated, completing raw material preparation, extrusion and puffing, sandwich, molding, cutting, spraying, seasoning, and final product production in one go. This core filling snack production line has the characteristics of multiple models, flexible configuration, wide range of raw materials, multiple product types, and simple operation. Choosing the appropriate configuration can produce products such as sandwich cakes, sandwich tubes, puffed rice and fruit, wheat roasting, Guoba, nutritious breakfast, corn flakes, etc.

The equipment of the core filling snack production line is highly automated, covering raw material preparation, extrusion and puffing, sandwich, molding, cutting, spraying, seasoning, and final product production in one go. This production line has the characteristics of multiple models, flexible configuration, wide range of raw materials, multiple product types, and simple operation. Choosing the appropriate configuration can produce products such as sandwich cakes, sandwich tubes, puffed rice and fruit, wheat roasting, Guoba, nutritious breakfast, corn flakes, etc. The puffed food has a crispy taste, is easy to digest, and is easy to carry, making it an ideal snack food for consumers.

.jpg)

The puffed material after filling in the core filling snack production line is extruded from the mold hole, and needs to be pulled to the shaping machine. After two forming rollers are pressed, it is cut into puffed food with a certain length, uniform thickness and thickness by a cutting knife. At this time, the material cools down and the moisture content drops to 6% -8%.