The complete set of equipment for core filling snacks production line is completed in one go from raw material preparation, extrusion and puffing, sandwich, molding, cutting, spraying, seasoning to finished product, with a high degree of automation. This production line has the characteristics of multiple models, flexible configuration, wide range of raw materials, multiple product types, and simple operation. Choosing the appropriate configuration can produce products such as sandwich cakes, sandwich tubes, puffed rice and fruit, wheat roasting, Guoba, nutritious breakfast, corn flakes, etc. The puffed food has a crispy taste, is easy to digest, has a rich aroma, and is easy to carry, making it an ideal leisure food for consumers.

Process composition of core filling snacks production line equipment:

1. Mixing machine: Select different models of mixing machines according to the different production lines.

2. Feeding machine: Using a motor as the power for spiral conveying, ensuring convenient and fast feeding.

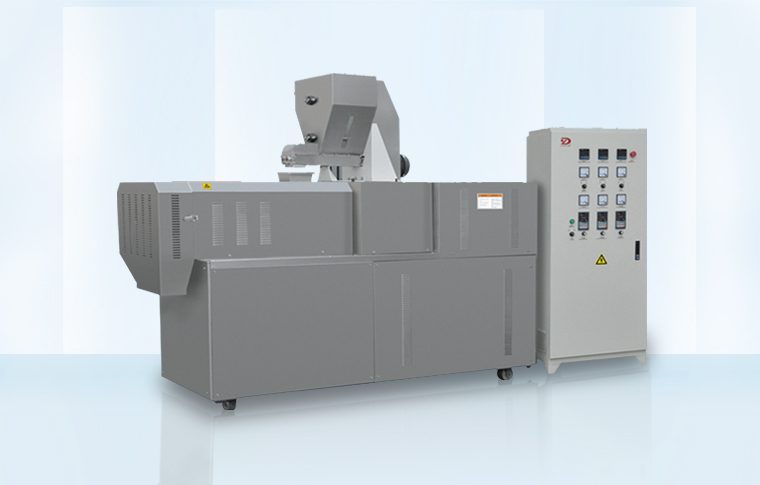

3. Expander: different models of DSE expansion mainframe are selected according to different production lines. The output can vary from 100kg/h to 150kg/h, and corn flour, Rice noodles, flour, cereal flour, etc. can be used as raw materials.

4. Core injection machine: When the puffing machine produces a hollow tube, the core material is instantly injected, which can be used to inject peanut butter, chocolate sauce, etc.

5. Plastic cutting machine: Cut the rice fruit with a core material, and the size of the rice fruit can be adjusted between 2cm-20cm.

6. Elevator: Transport the rice and fruit to the oven, and the height of the elevator is determined based on the oven.

7. Multi layer oven: The oven is mostly

The core filling snacks production line consists of a feeding system, an extrusion system, a rotary cutting system, a heating system, a transmission system, and a control system. Adopting advanced screw extrusion technology, the material is matured and expanded into shape using high temperature and high pressure, and completed in one go. The host adopts frequency conversion speed regulation to ensure the stability of the production process. The product features a variety of colors, beautiful appearance, natural realism, delicate texture, and a wide range of raw materials.