The nutritional rice production line adopts this process equipment to reduce or process the broken rice (broken rice, and shed rice germ) in the milling process into rice particles that are almost identical to ordinary whole rice, or according to the requirements of scientific diet, some natural nutrients such as various miscellaneous grains are mixed together in a certain proportion to make high nutritional rice and ready to eat snacks with the same cooking performance and cooking method (with flavor) as ordinary rice.

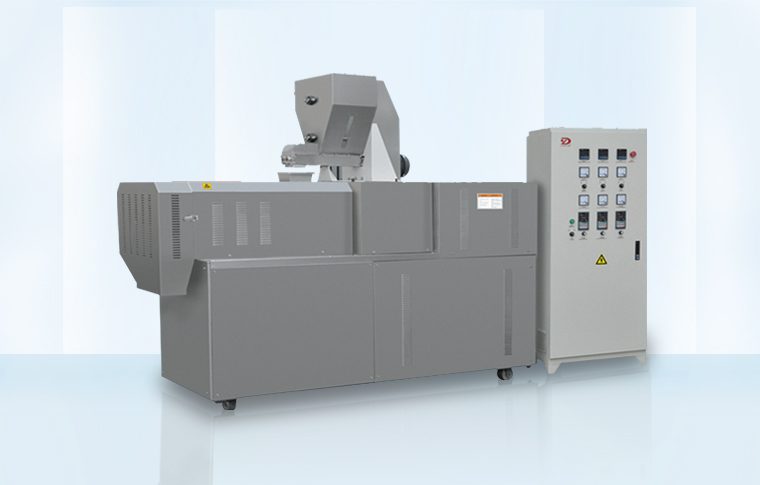

It is a food production equipment developed and produced by Jinan Dayi puffing machinery Co., Ltd. based on current food nutrition needs, combined with foreign technology foundation, suitable for modern enterprise production needs. This nutritional rice production line equipment adapts to the current situation of people’s dietary reinforcement treatment in modern society, meets people’s requirements for nutritional balance, and avoids the characteristics of large investment and high operating costs of introducing foreign equipment. At the same time, it has a high degree of automation and energy conservation.

This nutritional rice production line can use various grains such as rice, millet, black rice, buckwheat, etc. as raw materials, and add various vitamins, proteins, and minerals for processing. After being squeezed, matured, and shaped in an extruder, new fortified nutrition rice can be regenerated. Its consumption method is the same as natural rice and is simpler and more convenient, which is both nutritious and more adaptable to modern rhythm of life.

The fully automatic nutritional rice production line is developed to address the significant loss of nutrients in rice during traditional rice milling processes. Rice and its by-products can be made into high value-added products through extrusion technology. During this process, broken rice and rice bran can be reused. The entire production process is simple and easy to operate. After crushing the broken rice, it is mixed with a certain amount of water, oil, etc. At a certain temperature, the raw materials are matured in the extruder, and then extruded by a mold to form a rice shape. The reconstructed rice grains are then dried at low temperature. This squeezing technique effectively avoids the loss of nutrients, making it a nutrient rich fortified rice.